Ductless filtering fume hoods, as important and commonly used safety fume hoods in laboratories, have performance indicators that are critical to the safety and accuracy of laboratory work. The new National Standard Atlas “Design and Installation of Chemical Laboratory Ventilation Systems” 22K523, what specifications does it set?

Performance parameters

- The rated adsorption capacity of the fume hoods should not be less than the lower limit value of the rated adsorption capacity in Appendix B of the industry standard “Ductless filtering fume hood” JG/T 385-2012;

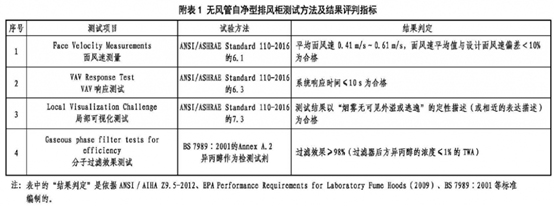

- The wind speed of the operating hole section of the operative air exhaust cabinet should be kept at 0.4m/s~0.6m/s;

- Suitability determination should be carried out before use, and the requirements should be referred to the industry standard, and the service life of the adsorption filter should be proposed according to the investigation results;

- Fault alarm response time should not be greater than 10s;

- The equipment noise during normal operation of a single exhaust cabinet should not be greater than 65dB(A).

Key safety indicators

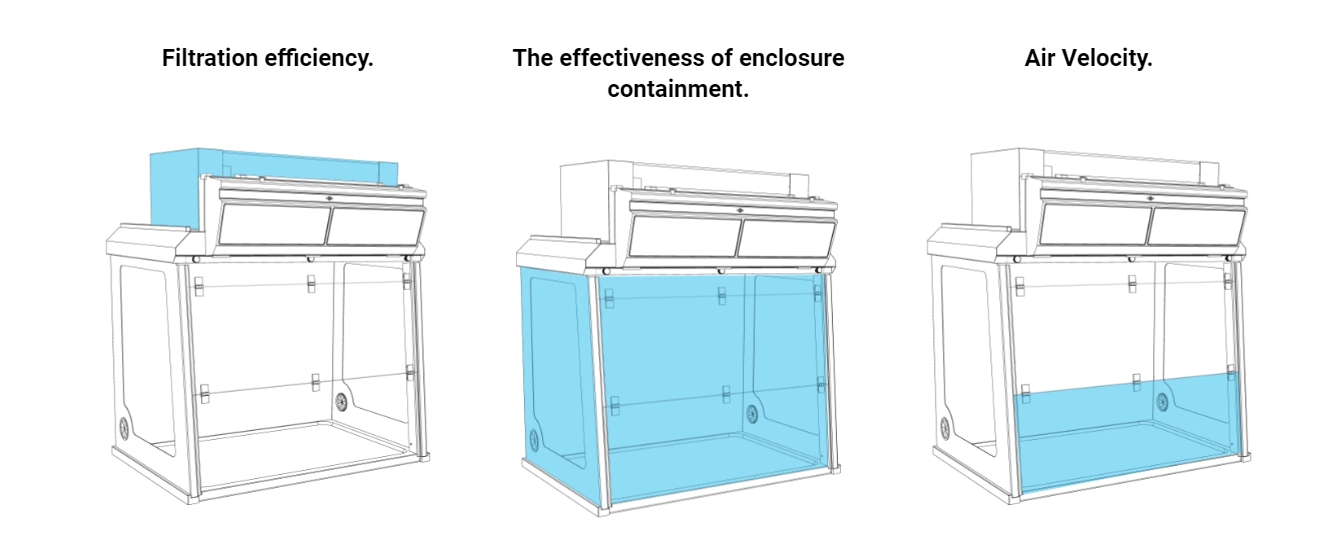

Filtration efficiency

Less than 1% of PC-TWA value

Containment

SF6 is used as a tracer gas, the leakage concentration should be ≤0.5ppm.

Air face velocity

Maintain at 0.4m/s-0.6m/s

Valiquest

Evaluate the suitability and service life of filters and issue a manual on chemical adsorption volume. It should also be noted that in the past, only the manufacturing test and test of the fume hood are available in China, but there is a lack of installation and operation test of the fume hood and ventilation system after the installation of the fume hood is completed in the ventilation system and during the operation.

This atlas draws on the same practice in foreign countries and suggests that before the completion and acceptance of the laboratory ventilation system, the fume hood should be installed and tested during the commissioning of the stand-alone test run.

Based on the national industry standards, Erlab has developed a specialized ESP safety process for the long-term commitment to protect the safety of users. Since the invention of ductless filtration technology in 1968, Erlab has not only strictly adhered to standards but also organized and participated in the preparation and revision of standards globally.