How can genomic centers, clinical labs, and healthcare facilities transition from manual low volume sample throughput too high throughput testing facilities, running 10k to 20k samples, per day?

The challenges that lie ahead of us

As the world faces challenges never before seen due to the current global pandemic caused by COVID-19, we all have concerns with what life is going to look like moving forward. But, before we start looking too far into the future, we have to deal with the current situation and the lack of testing capabilities. The current backlog of tests keeps growing and results typically take 3-7 days to receive. There simply has to be more throughput and facilities capable of receiving and safely processing a high volume of samples. So, how can genomic centers, clinical labs and healthcare facilities transition from manual low volume sample throughput (2,000 samples, per day) to high throughput testing facilities which can run 10,000 – 20,000 samples, per day?

Getting the facility prepared to handle potential contagious specimens

First, the facility’s directors will have to start drawing out plans to adjust airflow and perhaps even build temporary walls to segregate all Covid-19 testing from other areas of the lab and create cleanroom space. Along with the conversion of lab space, the CDC recommends that the laboratory should be a BSL2 facility at a minimum, which needs to be taken into consideration during re-design.

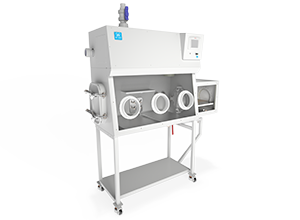

Secondly, the facility needs to consider equipment such as Bio Safety Cabinets (BSC’s) for sample preparation, where the sample goes through a process called Lysis, which is the breaking down of the cell membrane and aids in the separation of proteins.

How to choose the right CVE for your application

First, safety should never be overlooked and therefore the CVE should not only provide protection from spills, but they should also be equipped with H14 HEPA filters to capture any potentially aerosolized pathogens. In addition to having a primary HEPA filter, the CVE, or fume hood, should also have the ability to integrate an added level of H14 HEPA filtration for safety redundancy. To further increase the level of safety, the ability to also add carbon filtration should be available in order to adsorb all the emissions, which may be generated from the solutions used during the extraction process (e.g., chloroform, phenol, and ammonium).

Simplicity by Design

As the leader in products designed with simplicity in mind, Erlab’s Captair SMART Express CVEs require absolutely zero construction and are set-up-in quickly with in-house personnel. This is possible due to the unique design, allowing all hoods (CVE’s) to be shipped erlab-technician-replacing-filter-in-fume-hood (Completely Knocked Down) CKD and set-up within minutes of delivery. While simple by design, all hoods maintain the most important factor – safety. All hoods meet ASHRAE 110, AFNOR NFX, and ANSI Z9.5 standards, ensuring containment and filtration efficiency.

To learn more about Erlab products and services related to this industry visit our website today. For immediate assistance contact an Erlab Safety Expert. Call 844-300-8191 or email, captairsales@erlab.com.

About Erlab

Inventor of the ductless laboratory fume hood and worldwide leader since 1968, Erlab’s passion is to focus on the research and development, design, and manufacturing of cutting-edge toxic gas air filtration in the laboratory. As an industry innovator, Erlab is committed to safety, performance, energy efficiency, and sustainability, and has remained number one in the world for ductless fume hoods.

ADDITIONAL RESOURCES:

Safe Alternatives to Ducted Fume Hoods (Webinar)

See Is Believing – Demo of Captair Smart Ductless Filtering fume hood (Video)