Long before their headline grabbing use for overcoming PPE shortages, 3D printers have been used in Maker Spaces, Engineering Labs, R&D departments, and even homes across the globe.

The Hazards

Additive Manufacturing is a marvel of the modern world. Within hours, possibly even minutes, you can hold a pre-production version of a part to be used in a new design. Additive manufacturing technology, also called Fused Deposition Modeling (FDM), significantly compresses the product development life-cycle and lowers the cost burden of exploring new ideas and designs. All of this is good, great in fact, but brings with it some new concerns for safety.

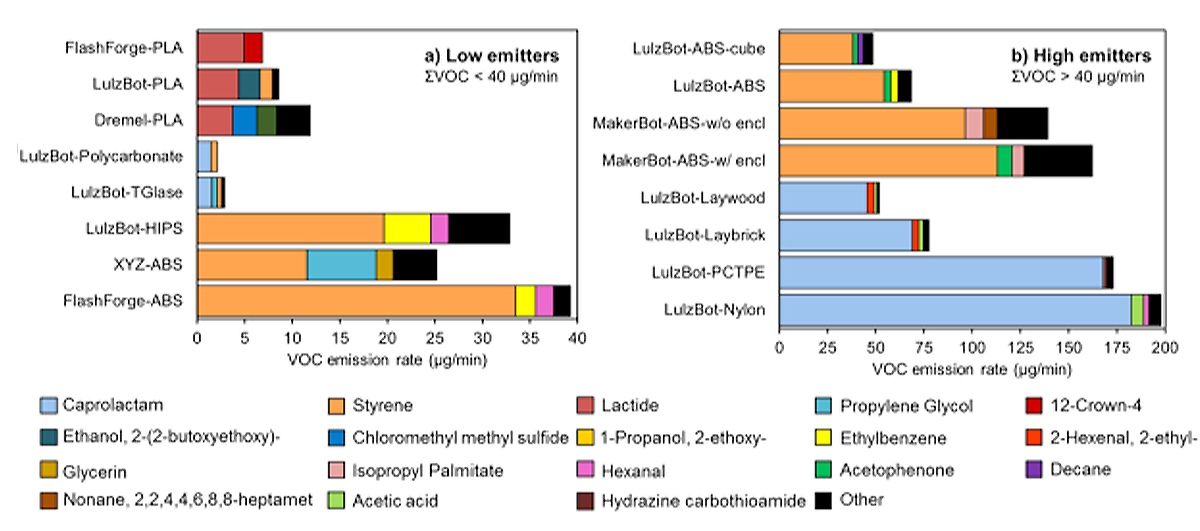

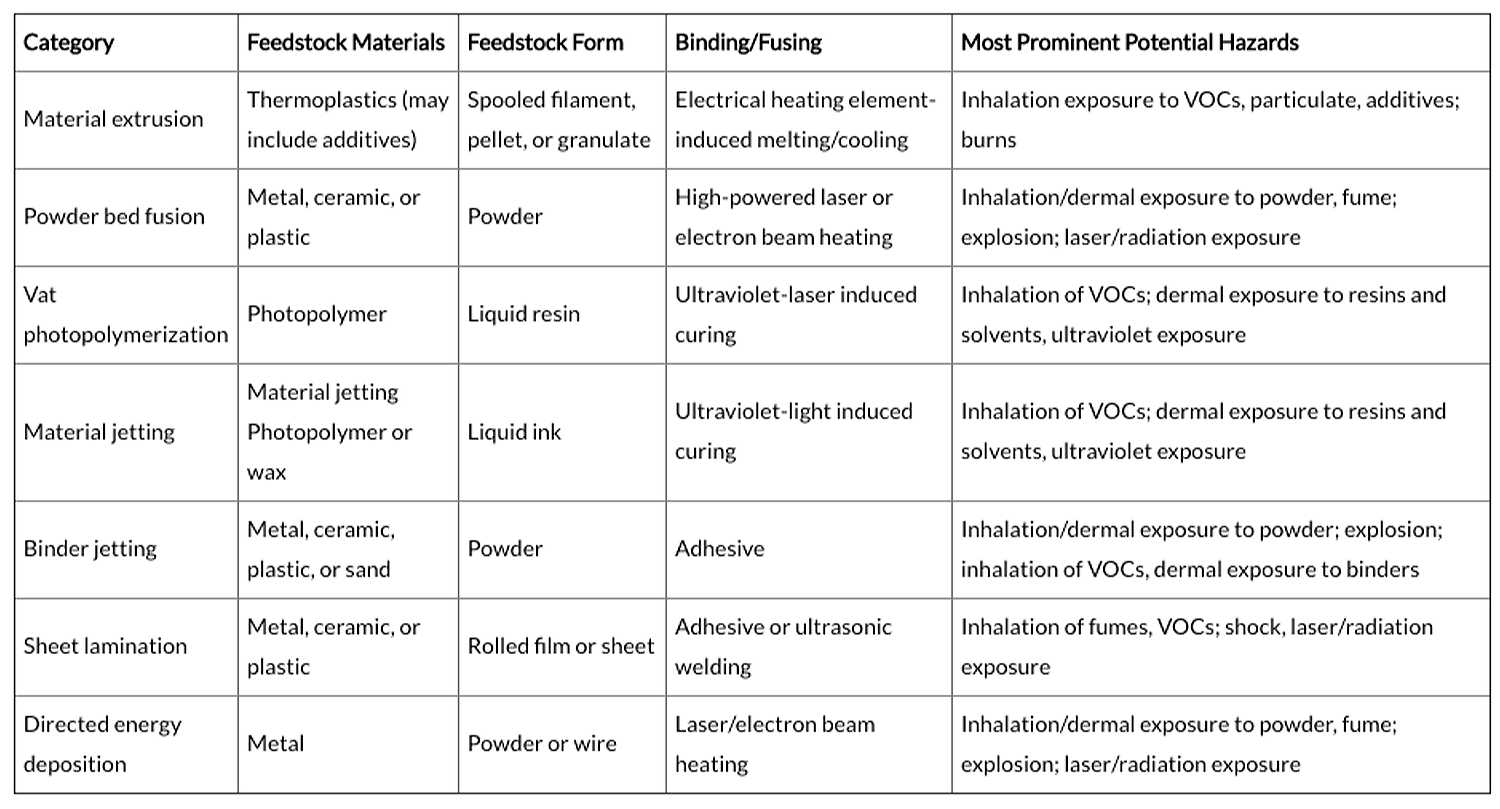

Depending upon the type of filament used for printing (e.g. PLA, ABS, Nylon, etc.), hazardous vapors, fumes and particles can be emitted in dangerous concentrations. Ultrafine Particles (UFP) present risks that are associated with lung damage and translocation to the bloodstream (NIH). Harmful Volatile Organic Compounds (VOCs) are emitted in varying degrees and are highly dependent upon the filament material being used. Frequent exposure to UFPs and VOCs is now associated with adverse health effects on the human body.

Image credit: P. Azimi, D. Zhao, C. Pouzet, N. E. Crain and B. Stephens, “Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments,” Environmental Science and Technology, vol. 50, no. 3, pp. 1260-1268, 2016

3D printing applications will also include post-processing methods to obtain the desired look and feel for your prototype. Cleaning, smoothing, welding, and surface finishing are all part of this process, and will require the use of chemicals (e.g. Dichloromethane, Ethyl Acetate, IPA, Acetone, THF). Such substances also pose a health hazard to the operator, which need to be addressed with safety measures.

As with most source generation, the further away you are the less concentration you’ll be exposed to and therefore the safer you should be. However in many cases, the 3D printer is needed close by to the workstation or occupied areas. Therefore, most 3D printers should be housed in a protective enclosure, or equipped with an exhaust system, that will capture and remove the airborne hazards from the air you breathe.

Safely Adding 3D Printers to Your Space

Reference: https://blogs.cdc.gov/niosh-science-blog/2019/04/09/am/

As our awareness of this emerging hazard increases, new test protocols and standards such as UL2904 are being developed and adopted by 3D Printer manufacturers. Additionally, customers are implementing their own safety protocols based upon best practices and discussions with their peers. For example, Cornell University’s EH&S Department has developed a 3D Printer Media Review on line, listing all the hazards of each type of media (aka filament) used. The Massachusetts Institute of Technology’s EH&S website lists the hazards on line also with excellent source material references.

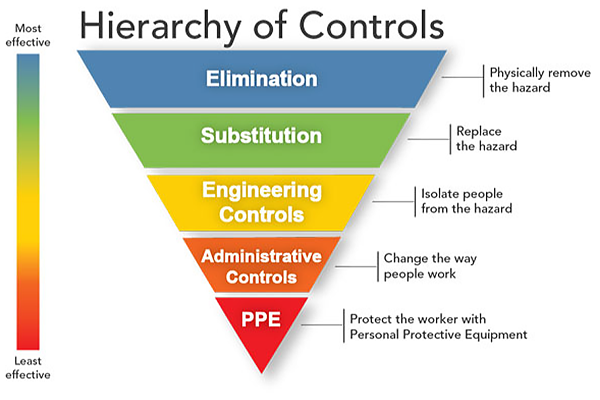

Eliminate Hazards First to Reduce Risks

The Hierarchy of Controls teaches us that elimination is the first step to reducing a risk. Since 3D printers are here to stay, we then must move to Substitution, the second step. Some filaments are less hazardous so substituting a lower temperature or otherwise safer filament is certainly worth investigating. But all filaments/media will emit some amount of vapors, nuisance odors and/or ultrafine particles. Distance and ventilation may be successfully used in large rooms, or areas with segregated ventilation, but in most cases capture and containment at the source is the safest path forward and this requires an engineering control, the third step in the hierarchy. Ductless filtering fume hoods are an engineering control that have been used for over 50 years.

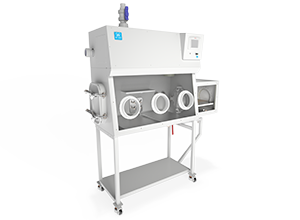

A ductless filtering fume hood system, also known as a Containment Ventilated Enclosure (CVE), isCS714_W3DPrinter a cost effective alternative to ducted exhaust systems which require make-up air to be brought into the room.

Ductless filtering fume hoods system can be equipped with both HEPA (particulate) and carbon (chemical) filtration, thus providing total protection to the 3D Additive Printer users.

This configuration allows the 3D Printer users to change filament materials and not be concerned about increasing the risk of exposure.

Simplicity by Design

With products designed with simplicity in mind, Erlab’s Captair SMART CVEsFiltering chemical fume hoods require absolutely zero construction and are set-up in just minutes. This is possible due to our unique design, allowing all hoods (CVE’s) to be shipped Completely Knocked Down (CKD) and re-assembled within minutes of delivery. While simple by design, all hoods maintain the most important factor – safety. All hoods meet ASHRAE 110, AFNOR NFX, and ANSI Z9.5 standards, ensuring containment and filtration efficiency.

Additional Resources:

A veteran safety experts shares the secrets of fume hood safety in the lab (Article)

Safe Alternatives to Ducted Fume Hoods (Webinar)

See Is Believing – Demo of Captair Smart Ductless Filtering fume hood (Video)