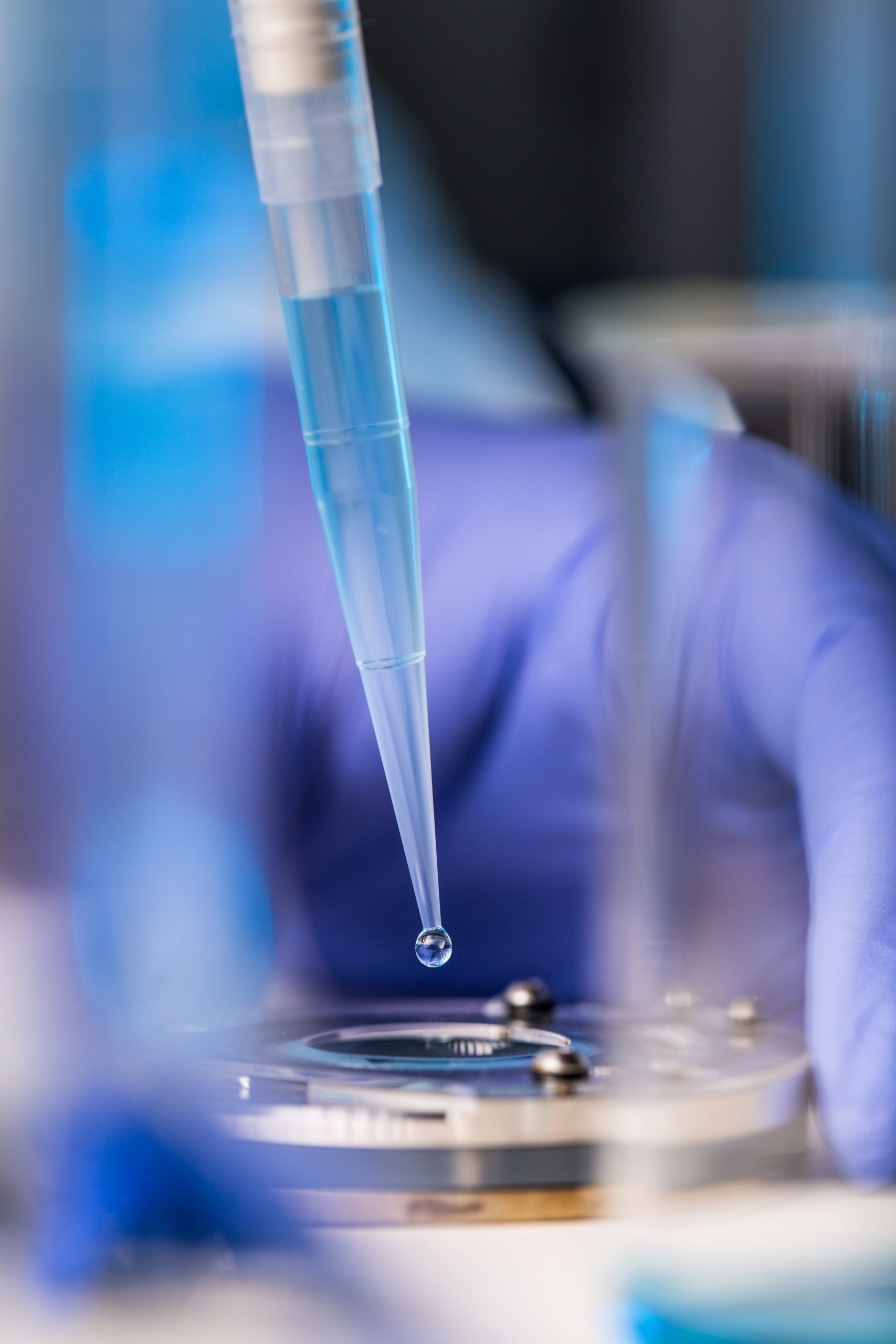

A Biological Safety Cabinet (BSC) is a laboratory device designed to protect users, the environment, and samples from microbiological agents. Primarily used in microbiology laboratories, this equipment creates a secure working area for handling potentially hazardous pathogens. Unlike standard laboratory fume hoods, BSCs are equipped with HEPA filters (High-Efficiency Particulate Air) that ensure a high level of particle filtration efficiency.

BIOLOGICAL SAFETY CABINET

Biological Safety Cabinets :

Advanced Protection for Biological Handling

What is a Biological Safety Cabinet (BSC)?

What is the difference between an BSC and a Laminar Flow Hood?

A Biological Safety Cabinet and a Laminar Flow Hood differ mainly in their purpose and level of protection. The BSC offers triple protection: it safeguards the user, the sample, and the laboratory environment. It is equipped with an airflow barrier that captures and recirculates air within the unit, preventing contaminants from escaping.

The Laminar Flow Hood protects only the sample by creating a horizontal or vertical laminar airflow, but it does not ensure the safety of the user or the environment.

If you handle hazardous substances or pathogens, it is recommended to use an BSC. In contrast, a laminar flow hood is suitable for less hazardous operations, such as cell culture, assembly of sensitive electronic devices, or preparation of cosmetic and pharmaceutical solutions.

How does a BSC work?

The operation of a Biological Safety Cabinet is based on a controlled airflow and advanced filtration system to protect the user, the environment, and the samples from cross-contamination. The key functioning steps of an BSC include:

Controlled laminar airflow

BSCs use unidirectional airflow to create a physical barrier between the user and the handled microorganisms. Air is drawn into the unit and passes through HEPA filters, removing over 99.97% of particles as small as 0.3 microns, preventing the escape of pathogens from the workspace and contamination of the laboratory environment.

Recirculation and exhaust air filtration

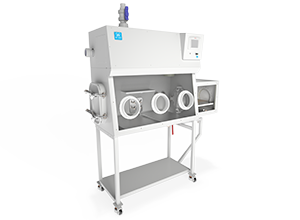

In Type II and Type III BSCs, contaminated air inside the cabinet is recirculated and filtered through multiple HEPA filters. Type II BSCs partially exhaust air outside the unit, while the other portion is returned to the working space. Type III BSCs, the most secure type, are completely sealed and connected to an external ventilation system, ensuring that all air is expelled outside the laboratory.

User protection

This combination of airflow and filtration protects the user from hazardous particles by preventing airborne microorganisms from leaving the workspace. The incoming airflow barrier also prevents external contaminants from reaching the sample.

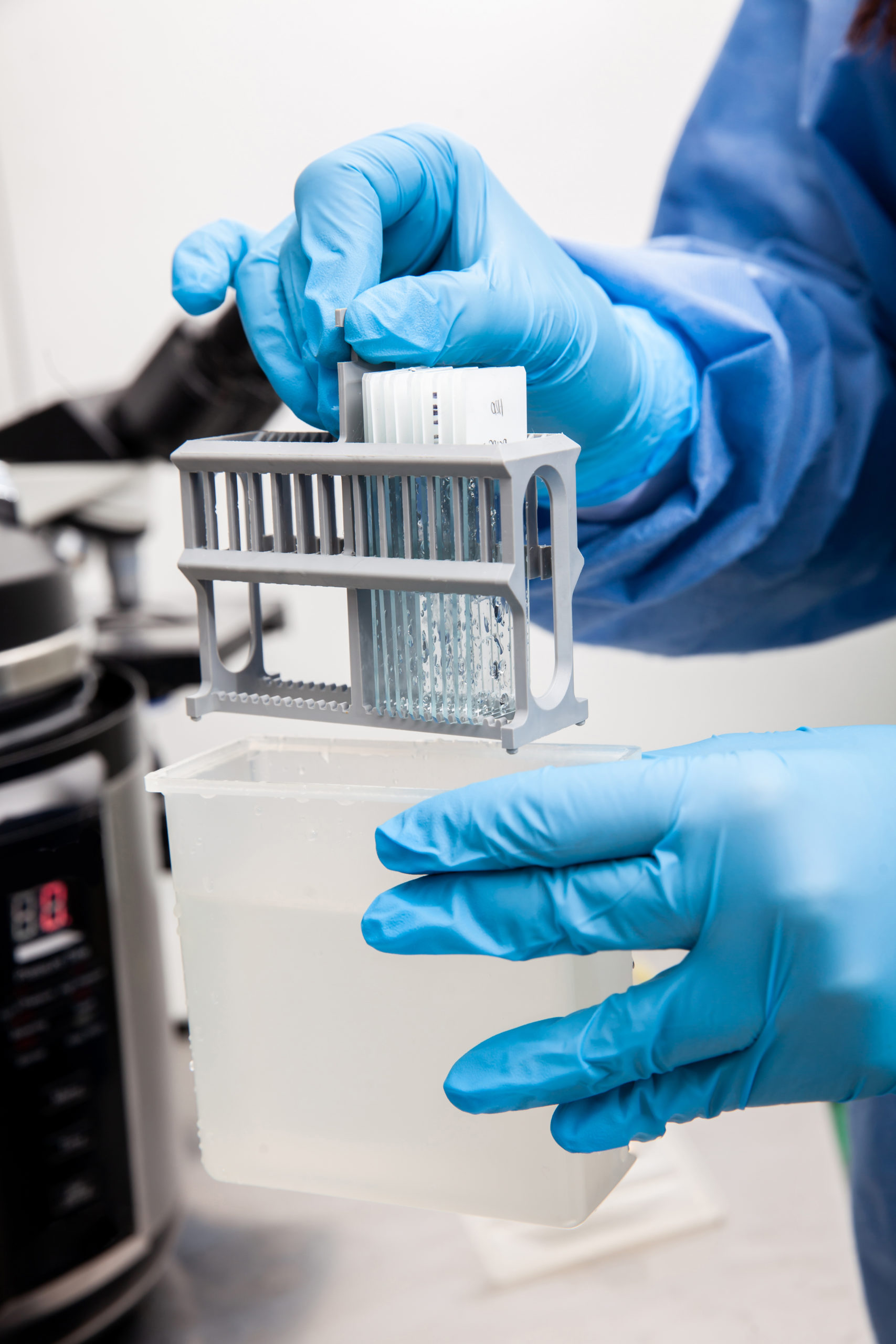

Sample protection

The clean filtered airflow maintains a sterile work environment, preventing cross-contamination between samples. This ensures optimal conditions for accurate and reliable research or diagnostic applications.

Why use a Biological Safety Cabinet?

A Biological Safety Cabinet (BSC) is an essential device for laboratories handling pathogens or potentially hazardous biological samples. Its primary role is to protect the user, the environment, and the samples by preventing the spread of microbiological contaminants. By utilizing HEPA filtration technology, the BSC creates a protective barrierbetween the user and microorganisms, significantly reducing the risk of inhalation or contact contamination.

The BSC also minimizes cross-contamination between samples, which is crucial for ensuring reliable and accurate research results. By using an BSC, laboratories ensure safe working conditions that comply with microbiological safety standards, a key factor in preventing laboratory accidents.

Advantages of Erlab BSCs

Ergonomics

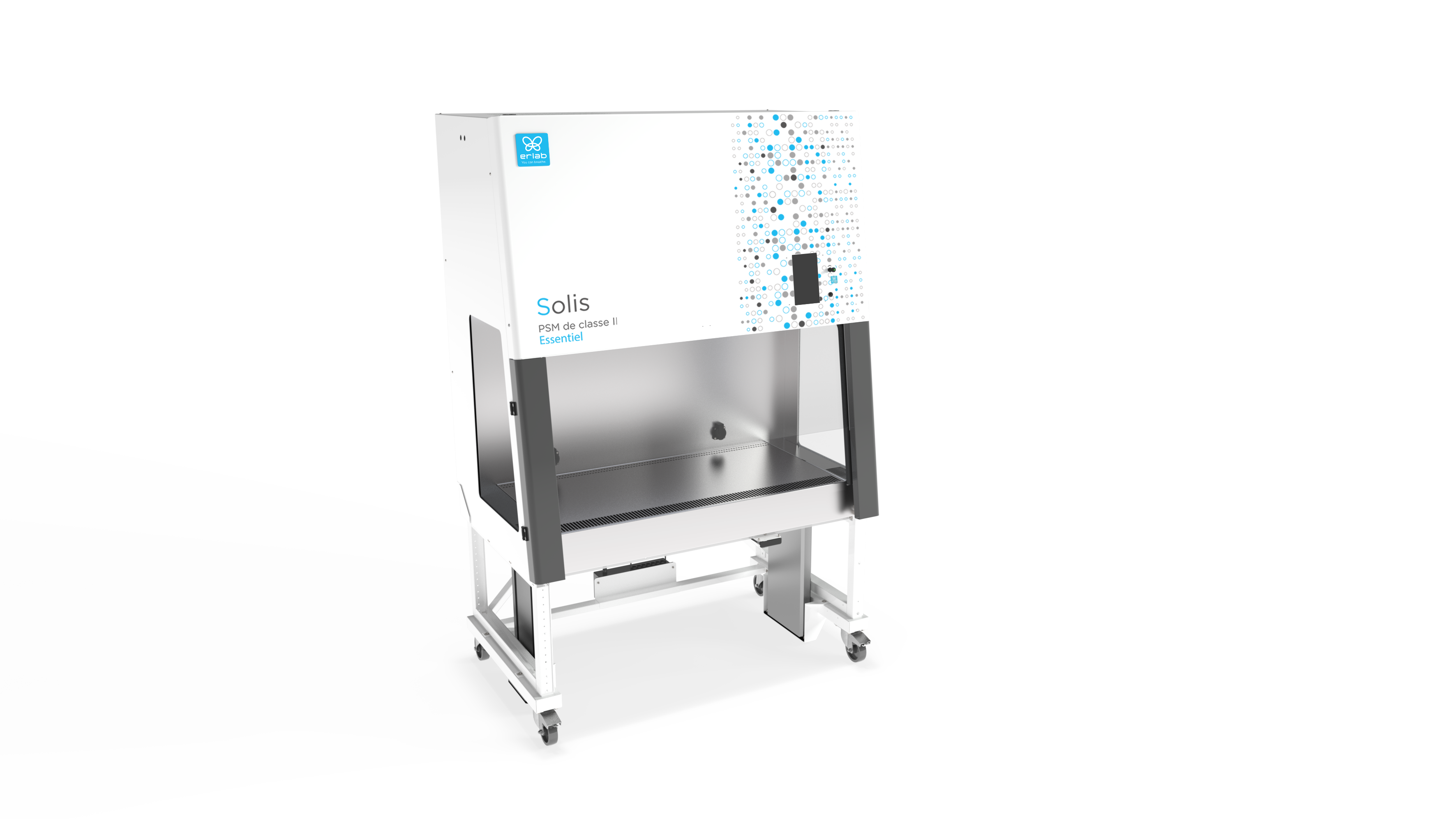

To facilitate interior cleaning of the front glass panel, the Solis microbiological safety cabinet is equipped with the patented Solis Twist and Clean® system.

This innovative system ensures complete cleaning of the glass surface, preventing microbial or bacterial proliferation that could contaminate handling.

Additionally, Erlab has developed a touchscreen interface on its BSC, allowing users to fully focus on their tasks. This intuitive and simple-to-use interface provides numerous features, such as device operation customization, safety information, and applications (timer, calculator, built-in camera, etc.).

For specific needs, Erlab offers custom solutions tailored to each laboratory’s requirements, including electric height-adjustable stands, UV decontamination, cable pass-through systems, electrical outlets, armrests, and footrests.

Mobility & Flexibility

Erlab offers various BSC models with different dimensions, allowing adaptation to space constraints in each laboratory.

In addition to providing recirculating units that do not require connection to an external exhaust system, Erlab offers BSC models with mobility wheels, enabling easy relocation within the laboratory.

Sample & Operator protection

he Solis Class 2 BSCs provide absolute biological protection for the operator, the handling process, and the environment against airborne contamination risks when handling Class 2 and Class 3 microorganisms and pathogens.

Equipped with HEPA H14 filters at both intake and exhaust, dual EC motor ventilation, and a high-efficiency airflow barrier, the Solis BSCs ensure a protected workspace for safe handling.

Erlab devices are designed and tested to comply with European Standard EN 12469-2000, which defines the minimum performance criteria for microbiological protection.

Choosing the right BSC for your laboratory

Choosing the right Biological Safety Cabinet (BSC) depends on several factors, including required containment level, type of biological agents handled, and laboratory-specific needs.

Determining the required protection level

To choose the correct BSC, it is important to consider several parameters, such as protection needs. Depending on the operations performed inside the BSC, selection should be based on one of the three BSC types.

The available space in the room also influences the choice. Type II BSCs are often available in various sizes to fit common laboratory layouts, while Type III BSCs, with their completely sealed enclosure, may require dedicated installation space. Laboratory layout and workflow should be considered to ensure optimal integration and user mobility.

Additionally, the comfort of the operator should be considered. Some BSCs include ergonomic features to ensure long-duration comfortable handling, such as Erlab’s BSCs, which offer significant advantages in ergonomics, flexibility, and protection.

Best practices for using a BSC in the laboratory

To ensure efficiency and safety when using a Biological Safety Cabinet (BSC), it is essential to follow best practices. Before any operation, make sure to clean and disinfect the interior of the BSC to eliminate any residual contaminants. Limit unnecessary objects in the work area to maintain an optimal laminar airflow. During use, avoid sudden movements that could disrupt the airflow and compromise sterility. Also, ensure that you wear the appropriate personal protective equipment (PPE), such as gloves and a lab coat, to enhance your safety. After each session, thoroughly clean the BSC and check the system indicators for any malfunctions. Finally, schedule regular maintenance, including HEPA filter replacement, to maintain performance and compliance with standards. By following these steps, you guarantee a safe and efficient working environment.