Posted by Ken Crooks, Director of GreenFumeHood Technology on Jun 3, 2020 8:52:18 AM

Success story: All upgrades at Butler Universities many labs were achieved without adding any additional HVAC. The cost of the renovation project was decreased by 10% and the annual operating cost was reduced by $51,000 per year.

THE SCOPE

Butler University, a private university located in Indianapolis, Indiana, is ranked #1 in midwest colleges by US News. The university offers impressive academic majors, with their chemistry and organic chemistry labs located at Gallahue Hall. Here students learn about the role chemistry plays in the synthesis of drugs and other molecules, as well as ways to measure water quality, how chemistry interacts with biology, and environmental science.

With the growing demand for laboratory usage, the existing HVAC system was inadequate to handle the air change required thus causing overwhelming noxious odors. This created tremendous air quality issues, forcing Butler to make a decision; either upgrade the HVAC system, which would have been a significant investment and not financially feasible, or look into alternative solutions that would be both cost effective, and, most importantly, safe.

Through detailed analysis of their options and a recommendation from BSA Life Structures to look into filtered fume hood options, it became clear that only filtration would provide a logical solution. Additionally this choice would allow for adding hoods, increasing safety in the lab, and provide flexibility for changes and future growth with no added HVAC infrastructure.

THE CHALLENGE

For Erlab and the BSA engineers it was critical to fully understand chemical handlingButler Lab_9 requirements within the hoods in order to provide an optimum solution. Critical to a successful outcome was determining a configuration that would allow maximum filter life while maintaining the stringent safety standards. It is especially challenging in an academic environment where changing curriculum requirements need to be anticipated in order to provide a solution that is flexible and adaptable for future needs. Erlab, sharing over 50 years of field expertise, worked with the teaching staff and EHS, as well as facility maintenance staff, to fully understand and bring the project to fruition.

THE SOLUTION

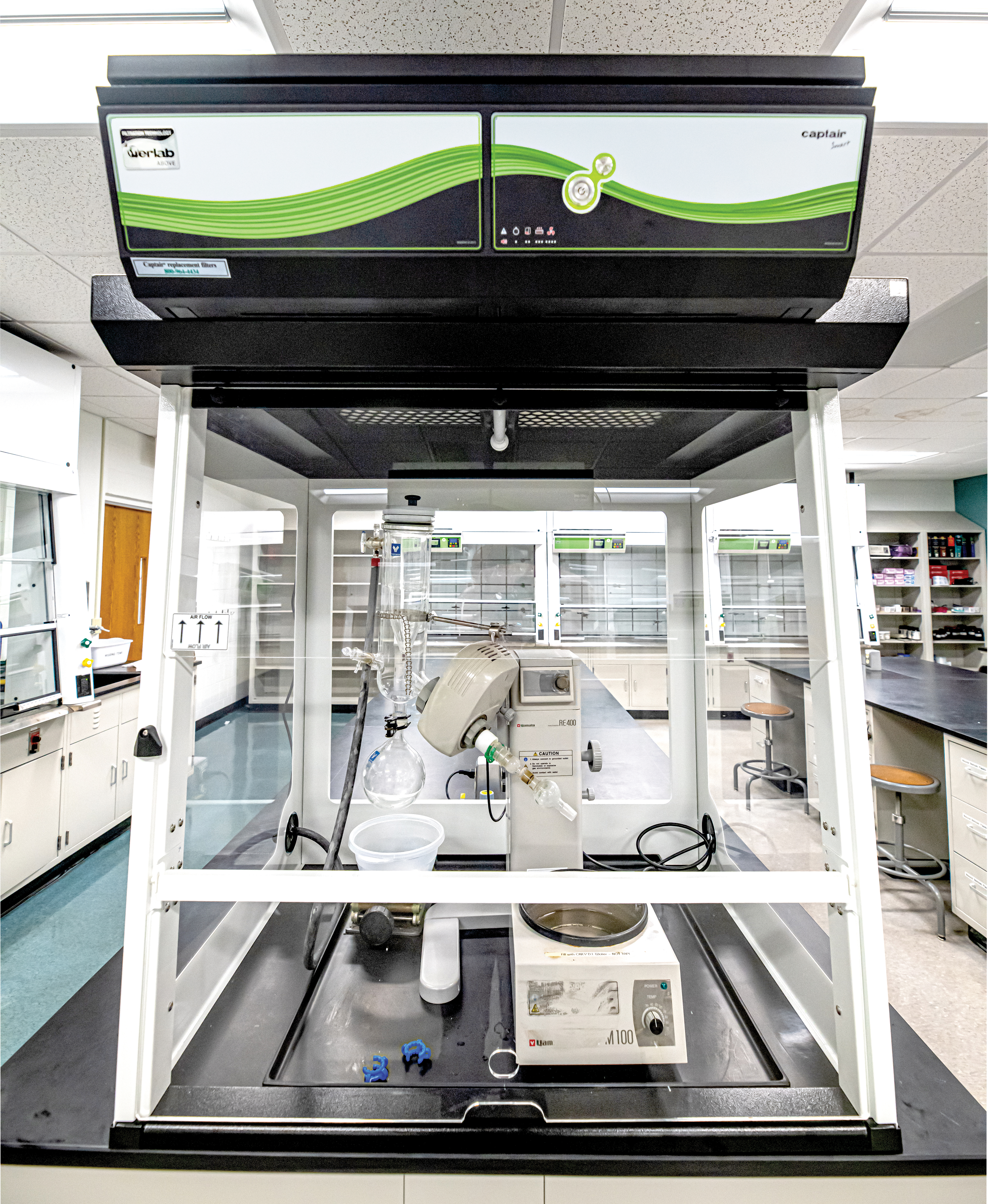

Butler’s fume hoods are utilized for a wide variety of applications that include pouring, transferring and refluxing procedures. To fully meet the chemistry labs needs, Erlab initially furnished (30) Green Fume Hoods that utilized its advanced filtration technology. Based on the success of the first installation, Butler decided to install (12) additional Erlab’s Captair filtered fume hoods for its rotary evaporators.

To further enhance student safety in the lab, Butler decided to leverage Erlab’s full eco system and added (2) Erlab Captair filtering storage cabinets and Erlab’s HALO whole room air filtration system in the synthesis lab. The Halo specifically addressed an issue of emissions, which were generated from their solvent recovery system.

All upgrades were achieved without adding any additional HVAC. The cost of the renovation project was decreased by 10% and the annual operating cost was reduced by $51,000 per year.

In addition to these significant savings, Erlab was able to improve upon the safety of the faculty and students, by providing:

- Increased safety through filtration, detection and communication

- Increased hood capacity

- Balanced rooms (proper pressurization)

- Improved indoor air quality

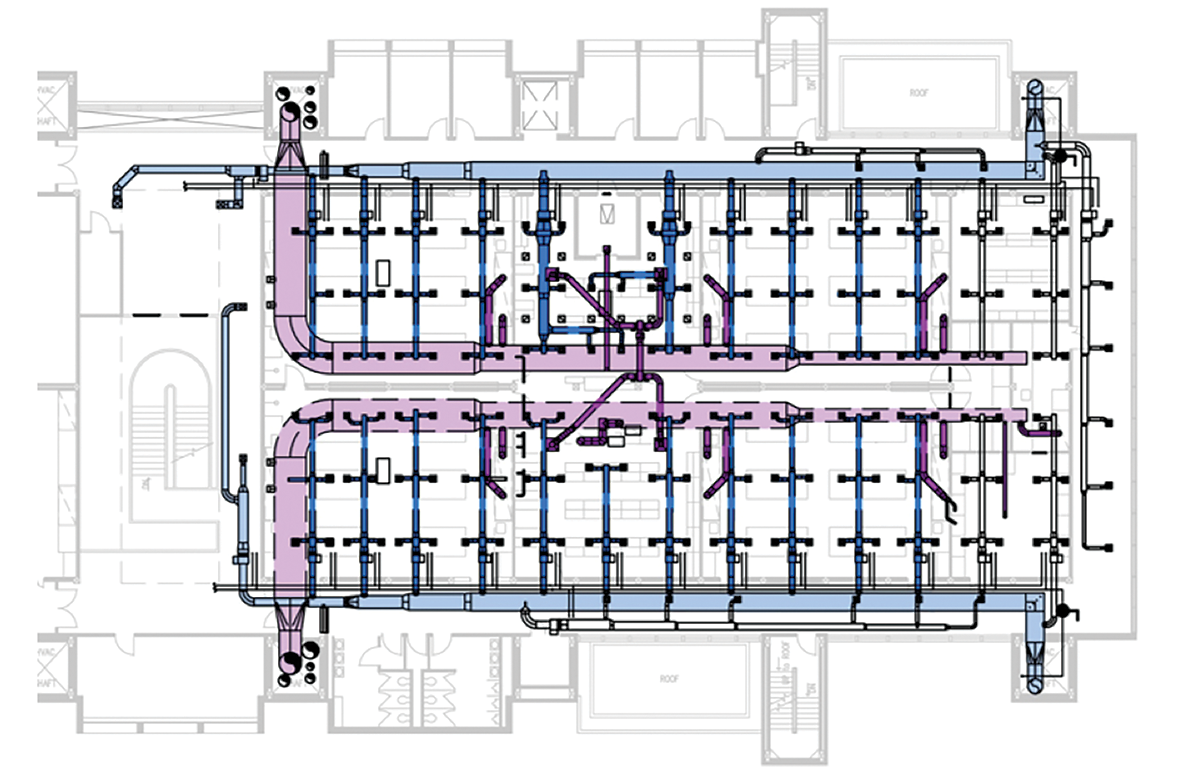

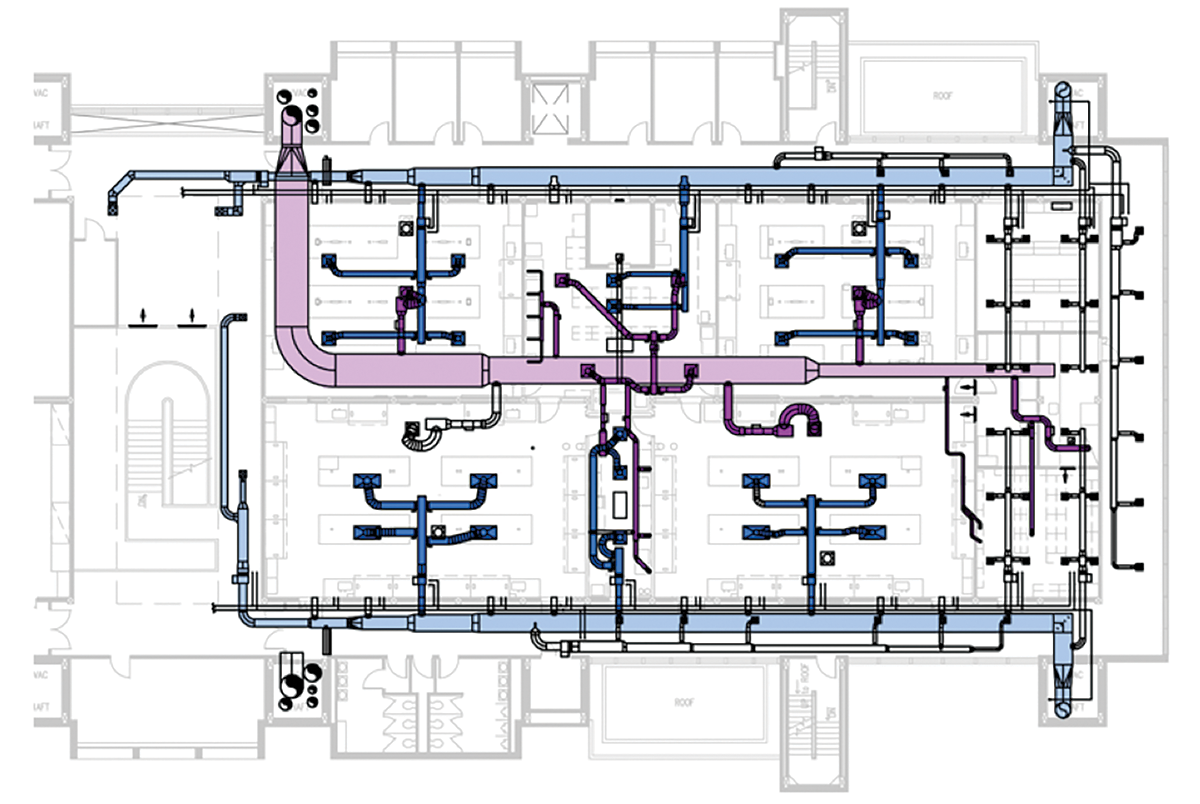

Diagrams of Chemistry Teaching Labs HVAC System:

BEFORE

AFTER INSTALLATION OF DUCTLESS FUME HOODS

THE RESULTS

After 5 years of continuous operation, the results are in and expectations were surpassed.

Operational impacts:

- 42% increase in student enrollment in the chemistry program

- $50,000+ annual operating cost savings.

- Filters lasted a full 5 years, 25% longer than expected.

- Improved IAQ and safety.

- Annual operating costs for each 6-foot hood is just $1,065, including periodic acid detector replacement.

Construction savings:

- $66,000 net construction cost savings (10% reduction).

- 3-month (27%) reduction in project timeline.

Erlab has been collaborating with Butler University for over 8 years, assisting in numerous laboratory upgrades that have added real value for their students and faculty.

« We have used the filtered fume hoods since 2010 Butler Lab_5in our teaching laboratories and have been very pleased with their performance. We have been able to manage routine maintenance on the hoods internally. Because of our experiences with the filtered fume hoods, we have also added several benchtop enclosures for rotary evaporators in our teaching and in our research labs. »

S. O’Reilly – Professor of Chemistry and

Biochemistry / Butler University